Products > TS-Series

TS01-M Custom MES Software for wire harness manufacturing

PRODUCT SUMMARY

The TS01-M MES software is an execution system designed for wire harness manufacturing. It reflects and refines the industry's advanced management systems and is tailor-made for wire harness manufacturing.

TS01-M covers production planning and equipment management, data analysis, team management and process management.

TS01-M has an intuitive and concise operational design, provides a smooth user experience, has powerful customizable functions, and has supporting SCADA software and hardware support.

It is easy to connect existing mainstream harness manufacturing equipment, and has a customized user ERP interface.

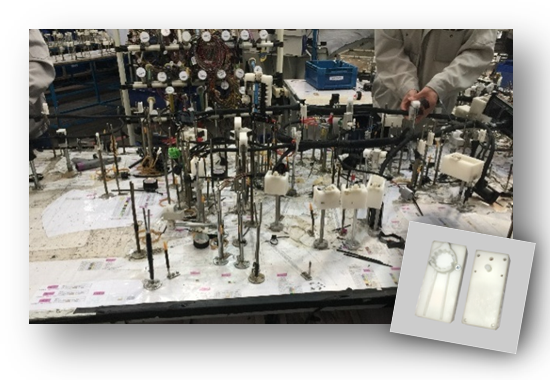

TS02 General SCADA Interface Card

PRODUCT SUMMARY

Powerful ARM CPU to handle communications and data processes

General purpose device configurable for major brand wire harness equipment such as cutting, twisting, crimping, housing insertion, welding, shrinking, taping and testing

Optional external touchscreen to manage login & Kanban, as well as machine data watch

Interface to equipment: ethernet, serial port & digital I/O by default, optional analog I/O & field buses

Interface to MES/ERP: wire/wireless ethernet

Optional data security by Blackberry or Trivers

Embedded design easy for existing machines’ SCADA upgrade

TS03 Wireless Self-powered Clip Detector

PRODUCT SUMMARY

Clip detection without any wires - 100% mobile

Clip detection without any battery or power supply - zero maintenance

Custom design options

First local brand, competitive service and price

TS04 Mobile Crimping Counter

PRODUCT SUMMARY

Mobile Crimping Counter with the size of a bottle cap, magnetically attached to crimping die with ease

Counter stores die ID and automatically counts crimping times

Counter communicates with mobile App via infrared to read/set data

Mobile App exchanges all data with die management center