Products > TR-Series

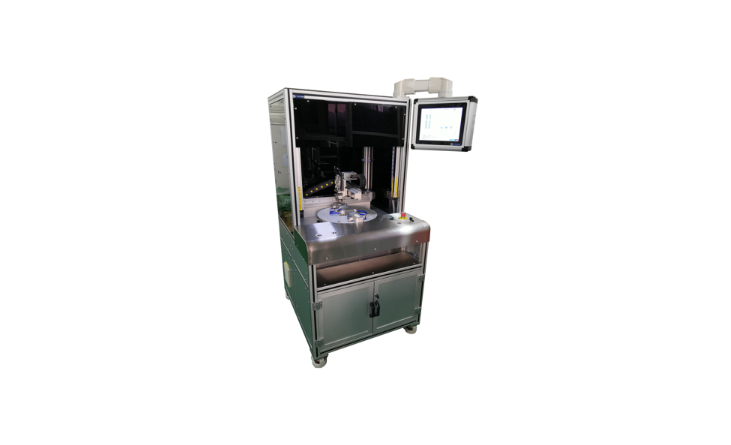

TR01 Housing Hole Punch

PRODUCT SUMMARY

The TR01 hole punch machine is specialized equipment for automatic hole punching and cleaning of connectors mainly used in the automotive wiring harness industry.

This series has two models: Single station and dual station.

We are able to customize the TR02 plug-in housing seal inserter into a seal insertion/housing hole punch dual-use device, please inquire for more information.

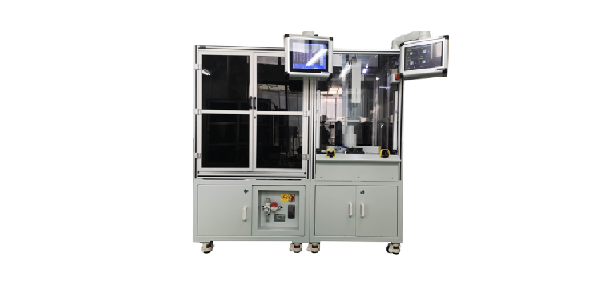

TR02-SM Robotic Housing Seal Inserter

PRODUCT SUMMARY

Highly efficient rotary table to support up to 3 inserting robots and up to 3 seal feeders for each robot

Yamaha robot with Keyence vision to deliver fast & accurate seal detection and insertion

Support both soft seals and hard pins

Full CNC control without any reforming dies required

Powerful functions of graphic process setup & real time tracing, fast positioning, automatic rework, vision QC, scan input, data communications & production stats

Quick interchangeable seal feeder, inserting head & housing fixture, automatic tooling match detection

Optional material handler, pin cutter & MES interface

TR02-Lite Housing Seal Inserter

PRODUCT SUMMARY

Patented technology of high-speed non-contact air jet seal insertion

Dual workstations to minimize idle time

Support most of regular-shaped seals, up to 3 seal feeders

Additional reforming mechanism to ensure depth consistency

Machine vision check for any misplaced insertions

Custom made fixtures with rich design database

Quickly interchangeable seal feeders, air-jet heads, reforming dies and housing fixtures

SCADA option for MES and production data center

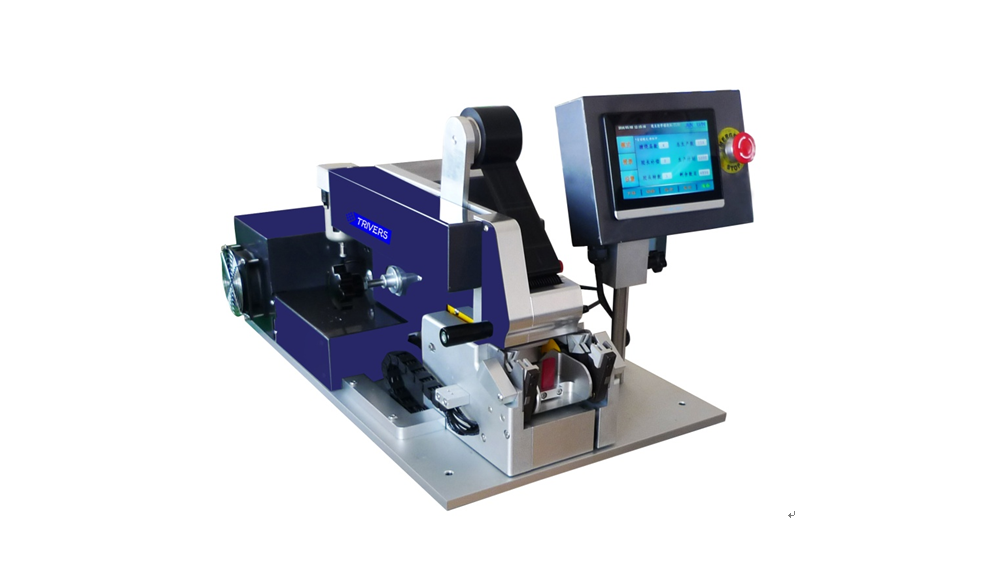

TR05 Series of Taping Machines

PRODUCT SUMMARY

Taping types: Spot/continuous taping

Easy to adjust: Speeds, turns, intervals etc

Compact size and light weight, fatigue-free to handle

Smart: Fault diagnosis, wireless network, cloud computing

Safeguard modes, automatic locker

Wide range of taping materials and wire sizes supported

TR05-DSK Desktop version

TR05 HCR Long/Thick Wire version

TR05 Mini/Std Handheld version

TR12-GN Handheld Cable Tie Gun

PRODUCT SUMMARY

Affordable tool for cable tie tightening and cutting

Light, compact & ergonomic design for frequent handling

3 levels adjustable to support tie width 2.7~7.2mm and pulling force 50~123N

5 fast-interchangeable heads for 0~5mm cut-off lengths

Supports suspension application

TR08-IDC Crimping Press

PRODUCT SUMMARY

Automatic pressure control & monitoring as well as press depth control & monitoring

Pre-press vision check for color & position

Post-press vision check for color, position & cover

Multiple-order manager, parameter tuning, graphic process display & shift testing

Alternate workstations for high efficiency

Custom design fixtures with rich database

SCADA option to connect machine to MES or production data station

APTIV global IDC supplier with installations in China and overseas

TR10 Welding joint Pull Tester

PRODUCT SUMMARY

High measuring accuracy

Embedded intelligent control system, consistent and accurate pull-testing

User-friendly interface, easy to use and simple to calibrate

Digital calibration and unit display conversion

Pull test for terminal wires (optional)

Collaboration with ultrasonic welder (optional)

Network connectivity with SCADA (optional)

TR48-CG-SM01 Finished Product

TR48-CG-KDS Finished Product

TR48-CG-KDS Raw Product

TR48-CG-ABF Corrugated Conduit Tubing (Pipe Threader)

PRODUCT SUMMARY

The TR48-CG-ABF pipe threading machine is a special equipment that replaces manual penetration of multiple strands of large wire harnesses tightly in a corrugated conduit.

The machine is mainly composed of several major components such as error-proof harness traction fixture, corrugated conduit anti-drag positioning fixture, harness arrangement sequence sensor, servo tie rod mechanism and electronic control system

TR48-CG-KDS Tight Tube Threading Machine

PRODUCT SUMMARY

The TR48-CG-KDS pipe threading machine is mainly used for a multi-strand wire harness with several meters in length. It can automatically put with a very tight wire casing greater than one meter in length. No lubrication is required, and the rest of the parts are automatically wrapped with tape.

This equipment sets corresponding orders according to the size and length of the casing model.

The operator only needs to operate the equipment and pick and place materials step by step according to the prompt of the operation light.

Different casing styles can be configured by changing the position of the casing clamp.

The control display shows real-time working conditions on processing progress, and that allows for processing parameters to be set.

TR48-CG-SM01 Rubber Seal Threading Machine

PRODUCT SUMMARY

TR48-CG-SM01 threading machine is mainly used to pass wires through a rubber waterproof hole in a housing. It is especially suitable for the scenarios where the waterproof hole is very tight.

The equipment can be customized for different tooling according to the size of the housing, the number and distribution of the wires passing through, and can insert different numbers of wires into different types of housing.

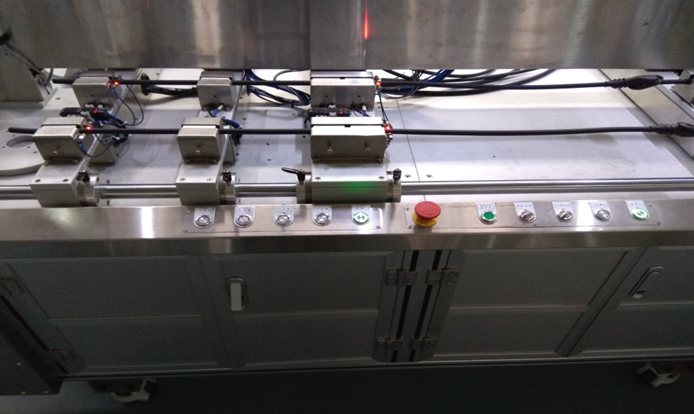

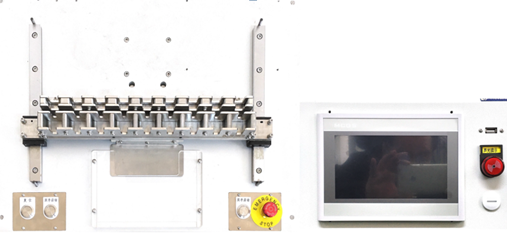

TR48-BJ-KDS Cable Stripping/Stranding machine (Dual station)

PRODUCT SUMMARY

The dual-station tube stripping/stranding machine is mainly used in the automotive wiring harness industry, which performs ring cutting on the cable and twists out cables, effectively stripping the outer protective layer of the cable stands within.

For different models and requirements, the stripping stranding machine parameters can be easily changed through the set by the HMI machine interface.